At its core, a power tool set is a collection of power tools and accessories, sold together as a single package. Instead of buying each tool individually, you get a curated kit that typically includes a combination of the most commonly used tools, batteries, a charger, and a case for storage and transport.

Think of it as a "starter kit" or a "core system" for tackling a wide range of DIY projects, home repairs, or professional tasks.

Key Components of a Typical Power Tool Set

While the exact contents vary by brand and price point, most sets include the following:

1. The Core Tools (The "Workhorses"):

-

Drill/Driver: The most essential tool, used for drilling holes and driving screws.

-

Impact Driver: Specialized for driving screws and bolts with high torque. It's often paired with a drill/driver in a set.

-

Circular Saw: For making straight cuts in wood, plywood, and other sheet materials.

-

Reciprocating Saw: A "sawzall" used for demolition, cutting pipes, pruning trees, and rough cuts.

-

Orbital Sander: For smoothing and finishing wood surfaces.

-

Work Light: A powerful LED light for illuminating your workspace.

2. The Power System (The "Heart" of Cordless Sets):

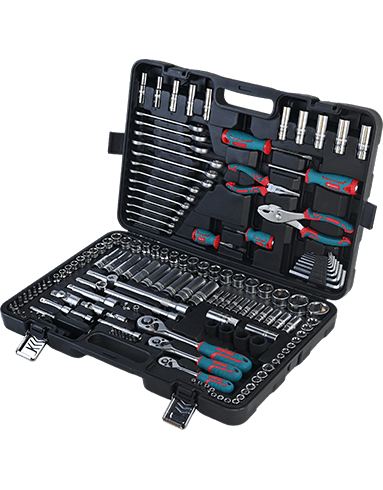

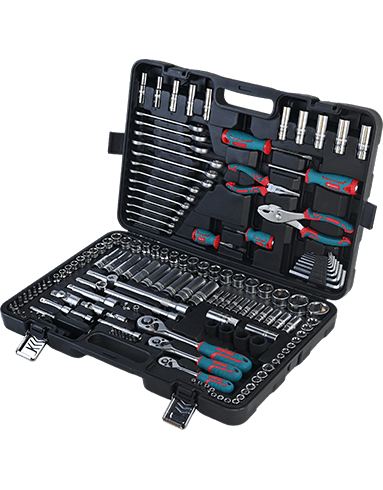

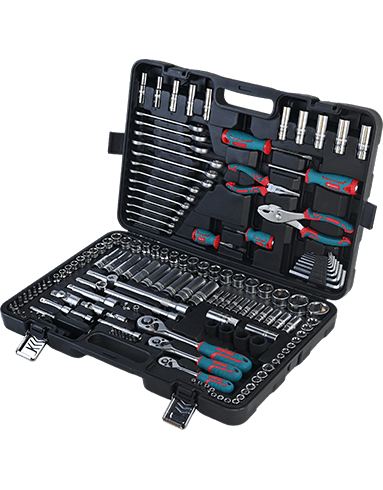

3. Storage and Accessories:

-

Carrying Case: A durable, often hard-shell case with custom-molded compartments to keep everything organized and protected.

-

Accessories: Most sets include a basic set of drill bits, driver bits, and sometimes a saw blade or sanding pads.